UNIMEC manufactures superb quality mechanical Screw Jacks and Bevel Gear Reducers with exceptional performance, absolute reliability and high accuracy. The use of a Screw Jack offers a variety of advantages such as its inherent self-locking mechanics allowing to maintain its position while supporting the load even in case of motor failures or power outages.

Ease of use and high reliability make UNIMEC trapezoidal screw jacks suitable for a wide variety of uses.They can be employed to lift, pull, move, or align any kind of loads, with a perfect synchronism which can hardly be obtained with other handling methods.

UNIMEC trapezoidal screw jacks are absolutely irreversible, that is, they can support their applied loads without needing any brakes or other locking systems.

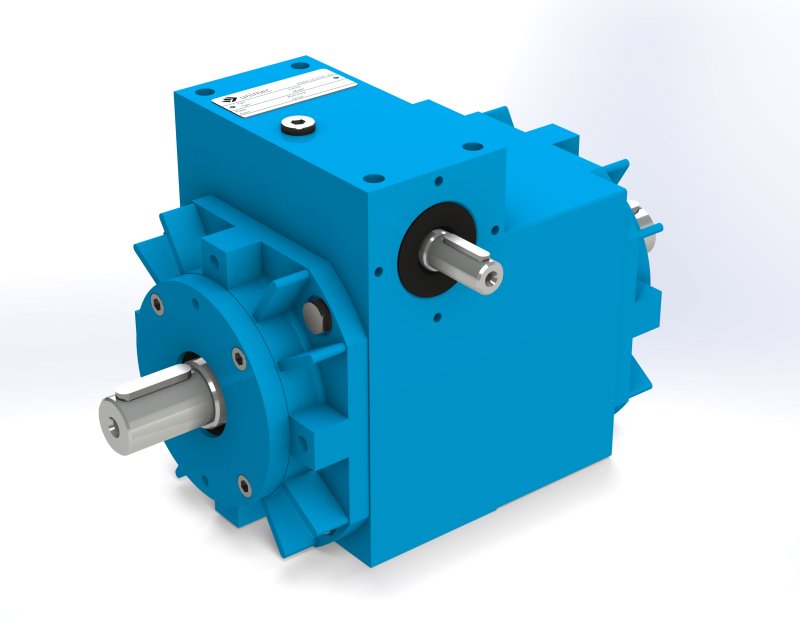

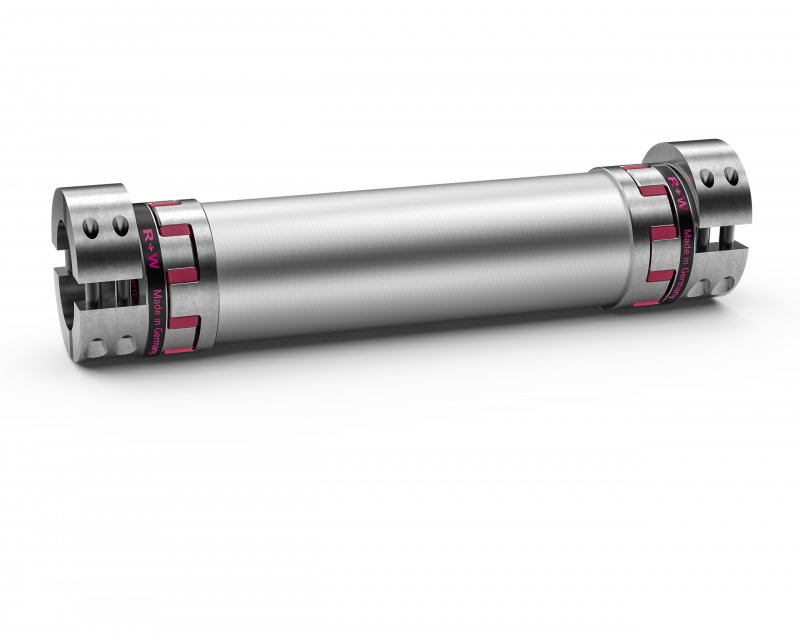

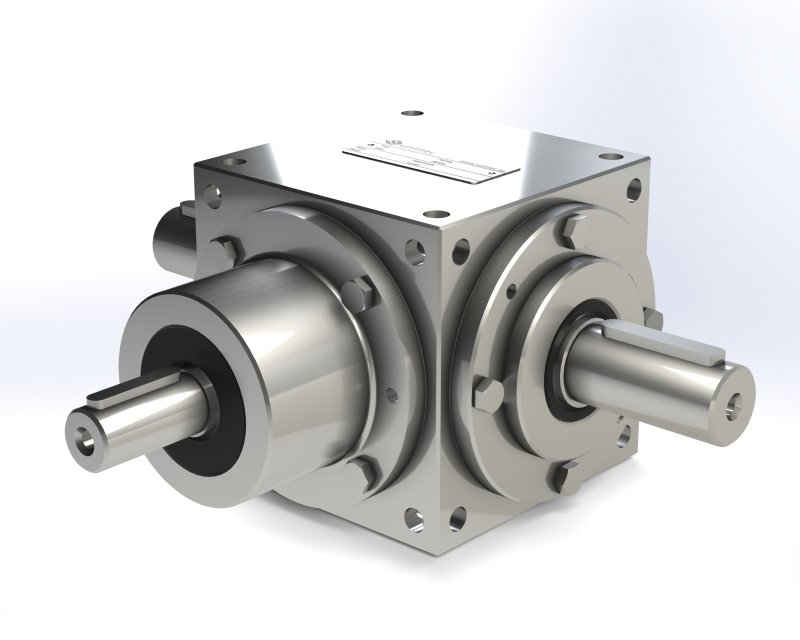

The screw jacks can be employed singularly or in groups properly connected with shafts, joints, and/or bevel gearboxes.

They can be driven by different motors: electrical, with either alternating or direct current, as well as hydraulic or pneumatic motors. Also they can be driven manually or with any other type of transmission.

In addition to the models shown on the following pages, UNIMEC can produce custom designed screw jacks to meet all the requirements. UNIMEC trapezoidal screw jacks are designed and manufactured using innovative technology so to supply a product which identifies itself with the state of the art in the transmission devices.

The highest quality and a 28 years long experience are able to meet the most demanding and sophisticated requirements.

The outer surfaces are completely machine finished and the parts are assembled with special care,

in order to allow the application of supports, flanges, pins, or any other components a project may require.

The application of double guides throughout the product line provides a very good running efficiency

even under the most strenuous operating conditions.

Special sealing systems enable the inner gears to operate in a bath of lubricant, which guarantees them a long lasting life.

INDUSTRIES

Marine

Marine

Food

Food

Steel

Steel

Aerospace

Aerospace

Automotive

Automotive

Drink

Drink

Paper

Paper

Construction

Construction

Nuclear

Nuclear

Solar

Solar

Machine Tool

Machine Tool

Plastic

Plastic

Metal Working

Metal Working

Entertainment

Entertainment

Telecommunication

Telecommunication

Train

Train

Pipeline

Pipeline

Glass

Glass